TECHNICAL FEATURES

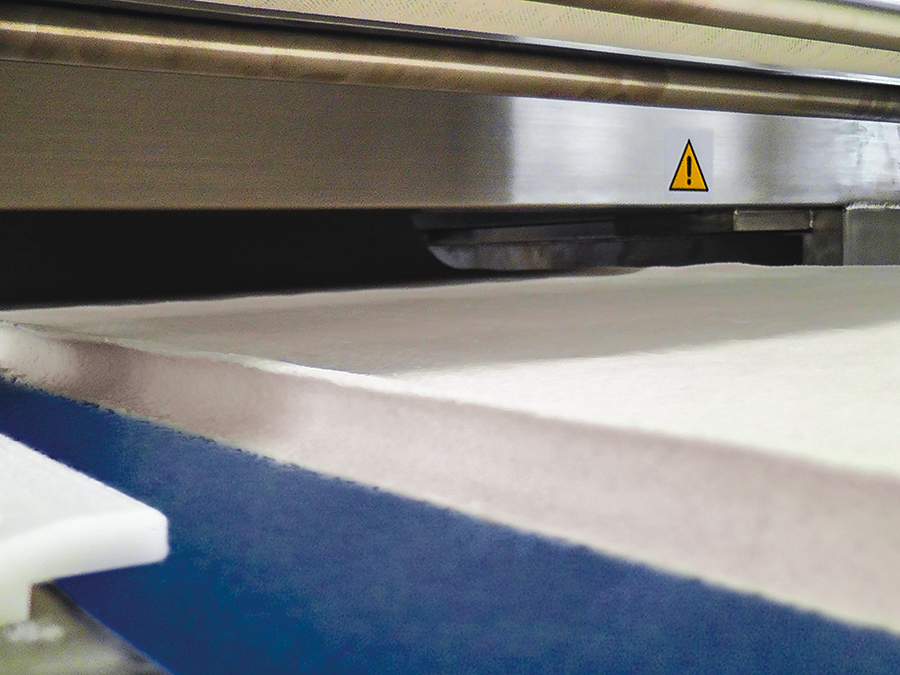

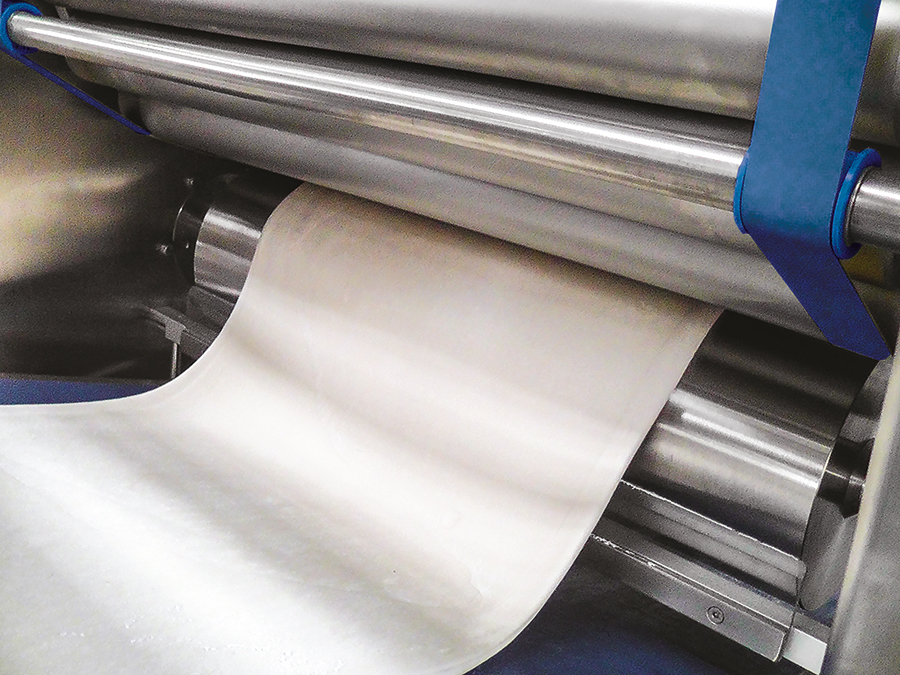

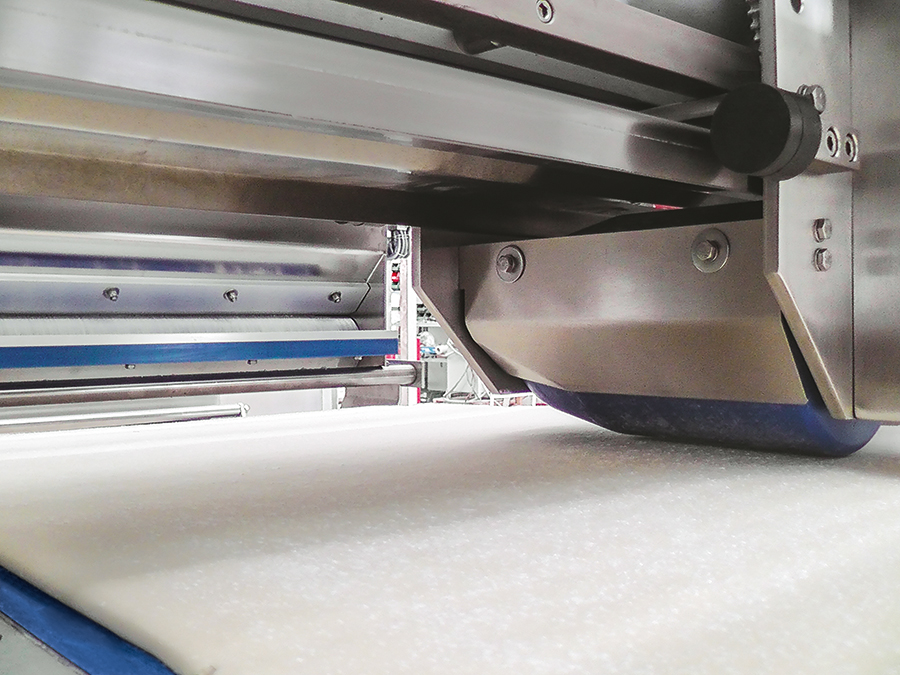

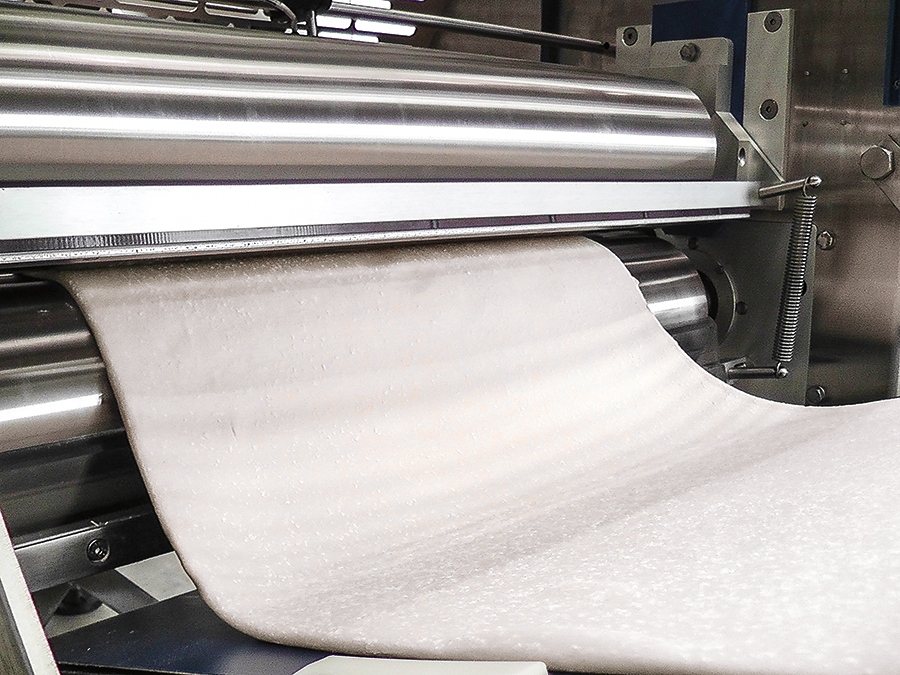

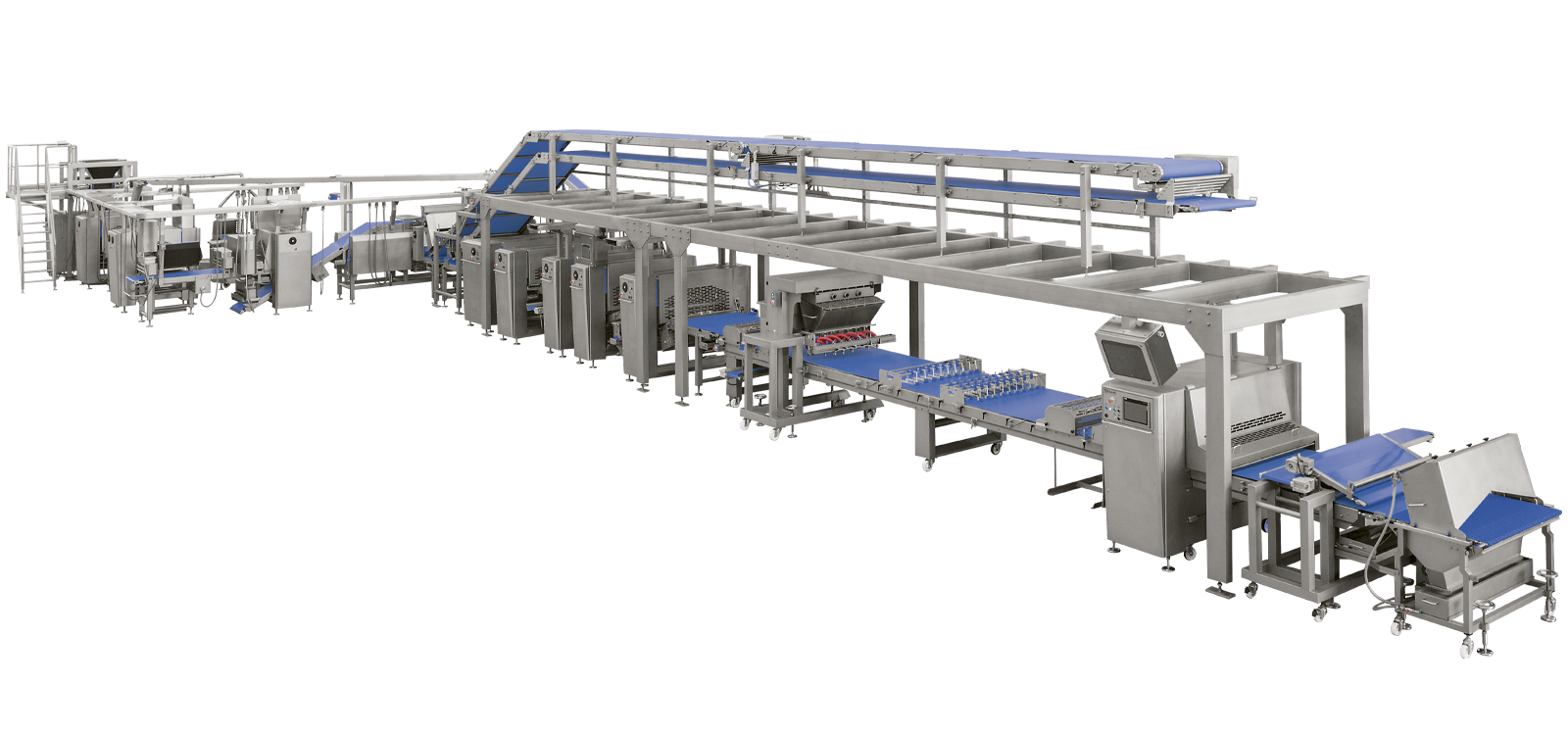

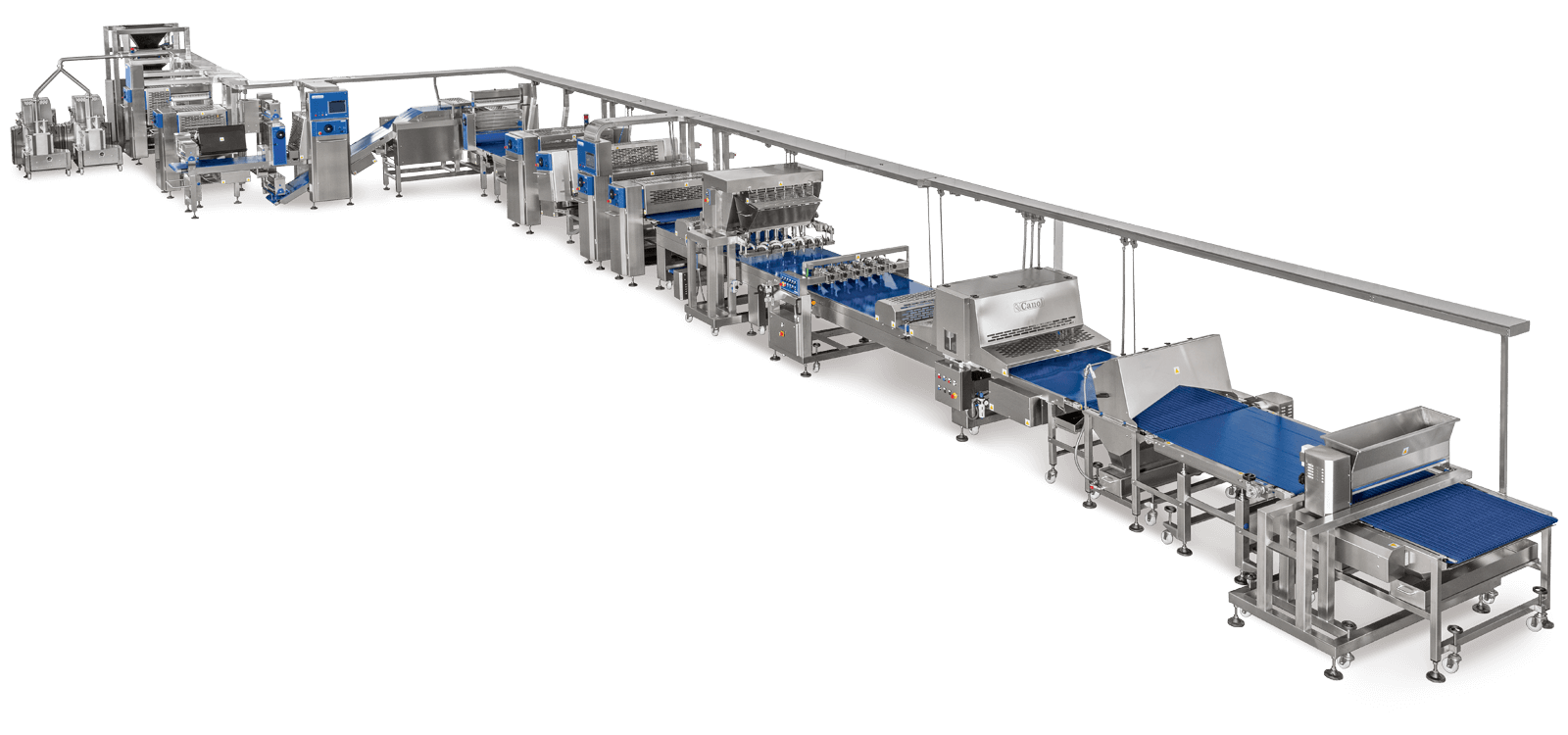

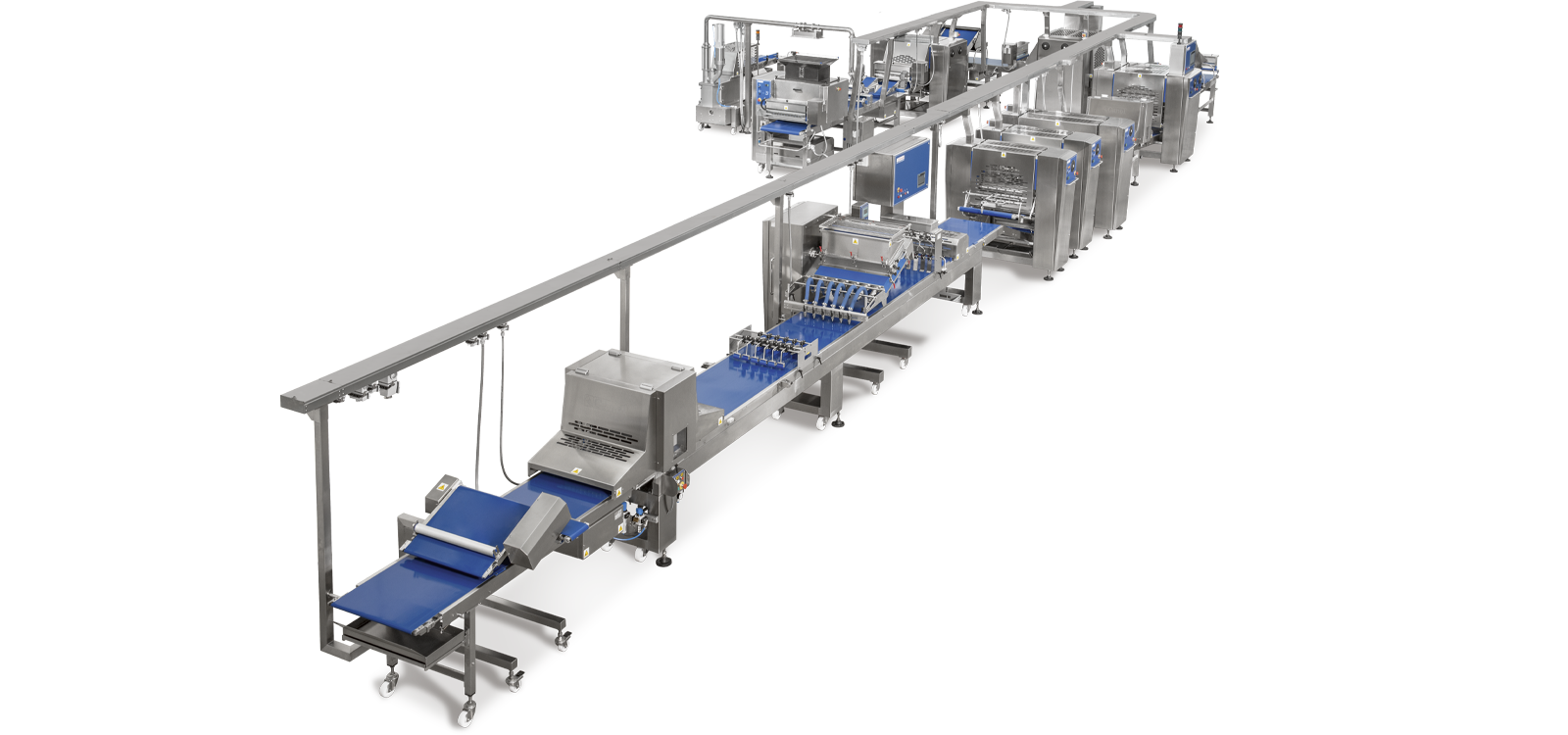

Our continuous laminating lines are suitable for the continuous production of high quality puff pastry, croissant and Danish dough, avoiding as much as possible any stress or tension on the dough thus guaranteeing quality and homogeneity to the products obtained.

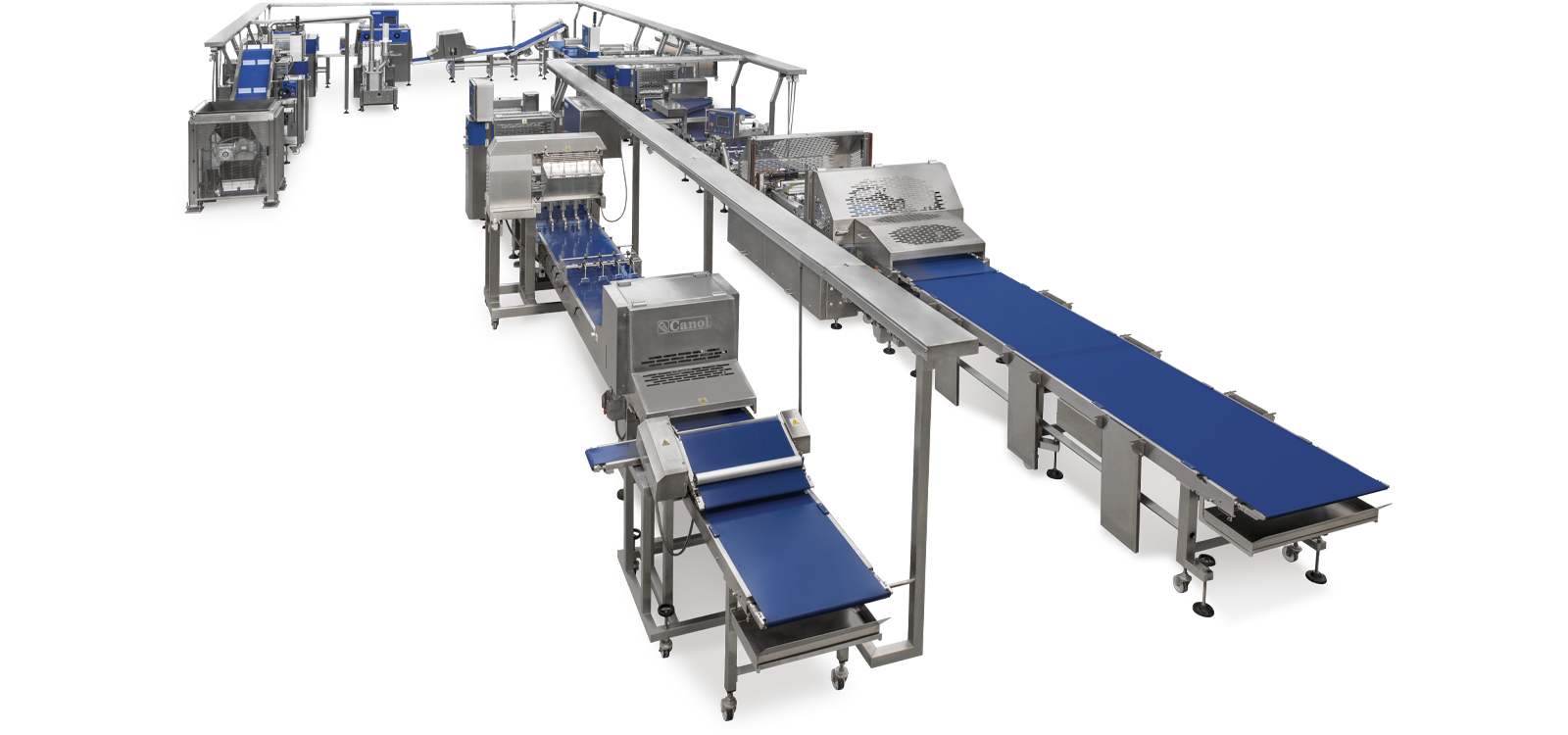

Our lines are designed in a modular way and therefore allow for their extension and integration in order to follow the development in terms of our customer’s production capacity and automation.

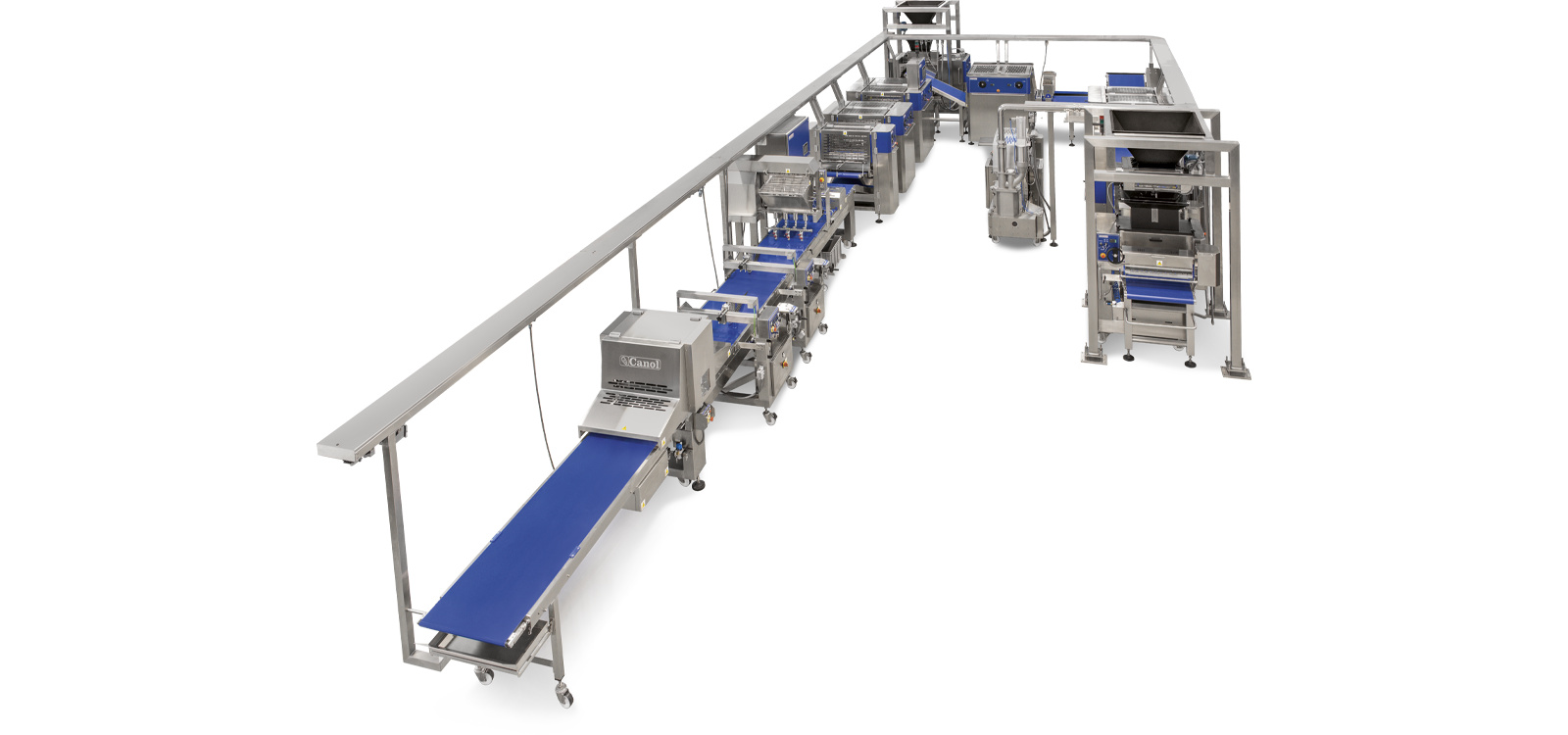

We offer laminating lines with different technical configuration, starting from the traditional “L”, “U” and “S” shapes to more specific and different shapes in order to satisfy our client’s requirements and space availabilities

Our Laminating lines can be integrated with dough resting belts and temperature /humidity controlled cells to combine the concept of high quality, dough resting and automation.

Canol lines are available in different working widths of 600 mm -800 mm- 1200 mm -1400 mm and other widths on request, in order to meet the production requirements of each customer.

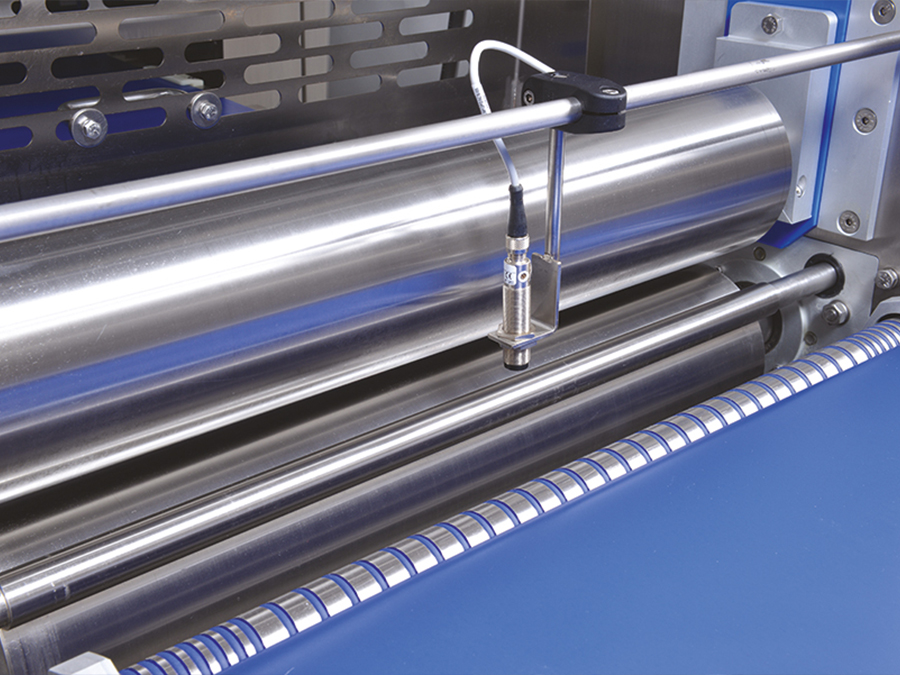

Our laminating lines are characterised by their reliability and feature innovative and highly advanced technological solutions that allow for intensive use and limited maintenance thanks to the high quality of the components used in our lines and the multiple checks at the construction level to which we subject each individual component.

Our laminating lines in industrial version are also designed according to hygienic design criteria that allow for an easier cleaning and avoid as far as possible the retention points of flour and dust in general, meeting the high hygienic standards required by the food industry.